Technologies and equipment

WaterJet technology

(water jet cutting)

EAGLE FIBER LASER CUTTING SYSTEM

BALANCING machine

CEMB

WaterJet technology (water jet cutting)

HOW DOES IT WORK?

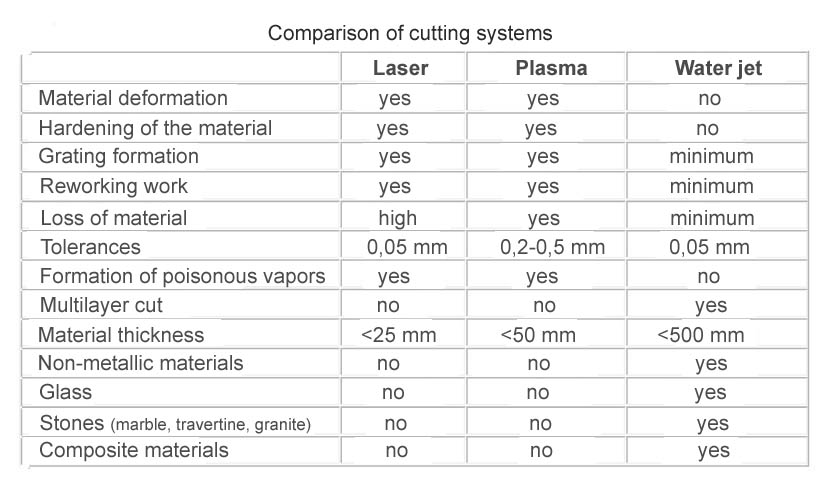

In the waterjet cutting system, called WaterJet, the potential energy that a pressure of up to 6,200 bar exerts on the water is switched into kinetic energy through a hard metal nozzle (MDI) just a few tenths of a millimeter wide. In this way the water becomes a jet that reaches the speed of 3 times higher than the sound.

This compact high energy jet is the real tool. One of the main advantages of waterjet cutting technology is certainly the fact that it represents a "cold" cutting system that is particularly delicate on metals, in fact the structure along the cutting edge remains unchanged, so there is no deformation or structural.

WHAT ARE THE BENEFITS?

The main advantages of the water jet:

1. The decrease in the development of heat leaves the structure of the metals homogeneous, usually saving expensive ripassature;

2. Narrow loss of material due to reduced cutting groove;

3. Possibility of cutting in every direction.

MACHINE CHARACTERISTICS

power: 6200 bar KMT

materials: all;

axes: 3 + dynamic system;

dimensions: < 500 mm

EAGLE FIBER LASER CUTTING SYSTEM

HOW DOES IT WORK?

WHAT ARE THE BENEFITS?

The main advantages of the laser system are:

- 2g acceleration

- Work area 1500x3000

- Linear motors

- Pallet change

- Linked to industry 4.0

BALANCING machine CEMB

WHAT ARE THE FEATURES

The main peculiarity of the system at a glance:

- model ZB3000 / G / GV

- rotating mass 3.000 Kg

- maximum rotating diameter Ø1.580 mm

- maximum length 2,970 mm

- Balancing speed 125-2,400 rpm

- minimum residual balance obtainable 0.1-0.3 g.mm/Kg

- Membership of Industry 4.0